CCB – Americas

Crosslinked polyolefin cable breakout boots

Heat shrink boots seal and protect multi-conductor cable and conduit breakouts.

Features and Benefits

- Shrink ratio accommodates a wide range of cables

- Flame retardant

- Boots for 2, 3 and 4 way cable breakouts

- Strain relief and mechanical protection

- Thermoplastic adhesive liner provides complete environmental protection and insulation

- Shrink ratio: >2:1

- Continuous operating temperature: -55°C to 100°C

- Shrink temperature: 135°C

Standards

- IEC 62677

- ESI 09-11

Typical Applications

Strain relief for multi-core cables, moisture sealing and environmental protection

Market/Applications

- Water/Waste Water Treatment

- OEM

- Power Distribution

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Petrochem/Pulp & Paper

- Power Distribution – MV

- Utility

- Mining

Ordering

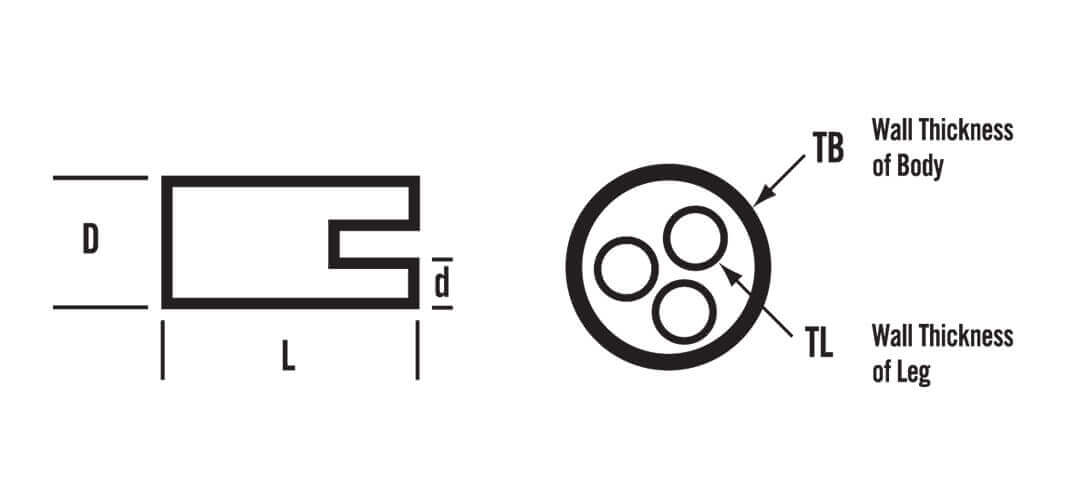

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Legs: 2, 3 or 4

- Please specify the product name, order number and options you require

- Order example: CCB, 0120, 2 legs

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Leg | Expanded | Recovered | Application Legs 600 V Conductor | |||||

| Diameter (Min) D |

Diameter (Min) d |

Diameter (Max) D |

Diameter (Max) D |

Length (Nom) L |

Wall Thickness of Body (Nom) TB |

Wall Thickness of Leg (Nom) TL |

|||

| no | mm (in) | mm (in) | mm (in) | mm (in) | mm (in) | mm (in) | mm (in) | awg/mcm | |

| 120 | 2 | 30 (1.18) | 15 (0.59) | 9.4 (0.37) | 4.1 (0.16) | 94 (3.7) | 1.5 (0.06) | 1.2 (0.05) | #10 – 2/0 |

| 200 | 2 | 50 (1.97) | 21 (0.83) | 22.9 (0.9) | 7.6 (0.3) | 119 (4.69) | 3.2 (0.13) | 3.2 (0.13) | #3 – 300 |

| 340 | 2 | 87 (3.43) | 43 (1.69) | 38.1 (1.5) | 12.7 (0.5) | 141.5 (5.57) | 3.8 (0.15) | 3.8 (0.15) | 3/0 – 1000 |

| 150 | 3 | 38.1 (1.5) | 16.5 (0.65) | 12.7 (0.5) | 4 (0.16) | 113.5 (4.47) | 2.9 (0.11) | 2.9 (0.11) | #8 – 3/0 |

| 170 | 3 | 43.2 (1.7) | 20.8 (0.82) | 22.9 (0.9) | 7.6 (0.3) | 99 (3.9) | 3.8 (0.15) | 3.8 (0.15) | #3 – 300 |

| 220 | 3 | 55.8 (2.2) | 30.4 (1.2) | 22.5 (0.89) | 9 (0.35) | 180 (7.09) | 3 (0.12) | 2 (0.08) | #1 – 600 |

| 240 | 3 | 61 (2.4) | 31.8 (1.25) | 35.6 (1.4) | 12.6 (0.5) | 144.5 (5.69) | 3.8 (0.15) | 3.8 (0.15) | #3 – 750 |

| 280 | 3 | 100 (3.94) | 39.9 (1.57) | 27.9 (1.1) | 12.9 (0.51) | 210 (8.27) | 3.6 (0.14) | 2.5 (0.10) | 300 – 1000 |

| 350 | 3 | 90 (3.54) | 35 (1.38) | 34 (1.34) | 14 (0.55) | 200 (7.87) | 3 (0.12) | 2 (0.08) | 4/0 – 1000 |

| 430 | 3 | 110 (4.33) | 40 (1.57) | 35 (1.38) | 17.5 (0.69) | 178 (7.01) | 4 (0.16) | 3 (0.12) | 300 – 1000 |

| 490 | 3 | 125 (4.92) | 50.8 (2) | 59 (2.32) | 25.4 (1) | 283 (11.14) | 3.8 (0.15) | 3.8 (0.15) | 750 – 1000 |

| 140 | 4 | 35 (1.38) | 15 (0.59) | 12 (0.47) | 3 (0.12) | 95 (3.74) | 2.5 (0.10) | 2 (0.08) | #12 – 2/0 |

| 190 | 4 | 47.4 (1.87) | 21.5 (0.85) | 22.9 (0.9) | 6.4 (0.25) | 165.1 (6.5) | 4 (0.16) | 3.3 (0.13) | #6 – 350 |

| 240 | 4 | 60 (2.36) | 30 (1.18) | 22.9 (0.9) | 6.4 (0.25) | 202 (7.95) | 4 (0.16) | 3.3 (0.13) | #4 – 600 |

| 310 | 4 | 78.7 (3.1) | 35 (1.5) | 35.6 (1.4) | 12.5 (0.49) | 240 (9.45) | 3.3 (0.13) | 3.3 (0.13) | 3/0 – 1000 |

| 525 | 4 | 133.4 (5.25) | 35 (1.5) | 76.2 (3.0) | 14.00 (0.55) | 254.4 (10.02) | 4 (0.16) | 4.1 (0.16) | 4/0 – 1000 |