CCB – EMEA

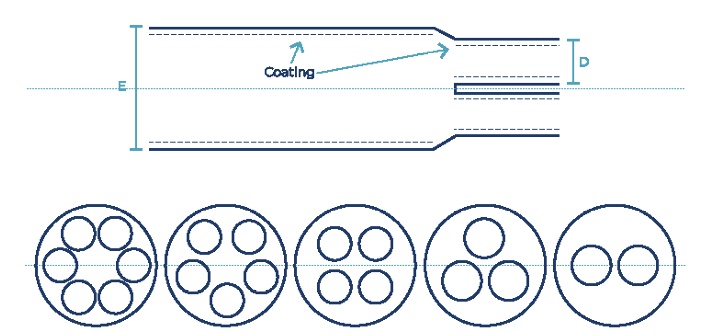

Crosslinked polyolefin cable breakout boots

Heat Shrink Boots seal and protect multi-conductor cable and conduit breakouts

Features and Benefits

- Boots for 2, 3, 4, 5 and 6 way cable breakouts

- Strain relief and mechanical protection

- Resistant to fluids and solvents

- Thermoplastic adhesive liner provides complete environmental protection and insulation

- Also available as anti-track medium voltage breakouts and as conductive breakouts

- Shrink ratio: 3:1

- Continuous operating temperature: -40 °C to 100°C

- Shrink temperature: 125°C

Standards

- IEC 62677

- ESI 09-11

Typical Applications

Strain relief for multi-core cables, moisture sealing and environmental protection, sealing and protecting wire connections in electrical vehicles

CCB2 – TWO CORE BREAKOUTS

CCB3 – THREE CORE BREAKOUTS

CCB4 – FOUR CORE BREAKOUTS

CCB5 – FIVE CORE BREAKOUTS

CCB6 – SIX CORE BREAKOUTS

Subject to technical changes

Market/Applications

- Water/Waste Water Treatment

- OEM

- Power Distribution

- Civil Construction Projects

- Power Distribution – LV

- Industrial

- Petrochem/Pulp & Paper

- Utility

Ordering

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Legs: 2, 3, 4, 5 or 6

- Printing: Printed or Unprinted

- Color: Black (BK)

- Please specify the product name, order number and options you require

- Order example: CCB3 38/11 black, unprinted, 350 pcs

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

CCB2 – TWO CORE BREAKOUTS

| Order Number | Breakout Main Diameter | Finger Diameter | ||||||

| Min | Max | Min | Max | |||||

| mm | in | mm | in | mm | in | mm | in | |

| CCB2 33/14 | 33.0 | 1.299 | 10.0 | 0.394 | 14.0 | 0.551 | 3.0 | 0.118 |

| CCB2 50/21 | 50.0 | 1.969 | 22.0 | 0.866 | 21.0 | 0.827 | 6.7 | 0.264 |

| CCB2 70/30 | 70.0 | 2.756 | 35.0 | 1.378 | 30.0 | 1.185 | 7.0 | 0.276 |

CCB3 – Three Core Breakouts

| Order Number | Breakout Main Diameter | Finger Diameter | ||||||

| Min | Max | Min | Max | |||||

| mm | in | mm | in | mm | in | mm | in | |

| CCB3 38/11 | 38.0 | 1.496 | 14.0 | 0.551 | 11.0 | 0.433 | 4.0 | 0.157 |

| CCB3 60/24 | 60.0 | 2.362 | 22.0 | 0.866 | 24.0 | 0.945 | 8.0 | 0.315 |

| CCB3 80/36 | 80.0 | 3.150 | 33.0 | 1.299 | 36.0 | 1.417 | 16.0 | 0.630 |

| CCB3 110/48 | 110.0 | 4.331 | 47.0 | 1.850 | 48.0 | 1.890 | 20.0 | 0.787 |

| CCB3 125/55 | 125.0 | 4.921 | 47.0 | 1.850 | 55.0 | 2.165 | 20.0 | 0.787 |

| CCB3 140/62 | 140.0 | 5.512 | 54.0 | 2.126 | 62.0 | 2.441 | 27.0 | 1.063 |

CCB4 – Four Core Breakouts

| Order Number | Breakout Main Diameter | Finger Diameter | ||||||

| Min | Max | Min | Max | |||||

| mm | in | mm | in | mm | in | mm | in | |

| CCB4 38/15 | 38.0 | 1.496 | 14.0 | 0.551 | 15.0 | 0.591 | 3.0 | 0.118 |

| CCB4 55/20 | 55.0 | 2.165 | 25.0 | 0.984 | 20.0 | 0.787 | 6.0 | 0.236 |

| CCB4 72/25 | 72.0 | 2.835 | 22.0 | 0.866 | 25.0 | 0.984 | 8.5 | 0.335 |

| CCB4 100/35 | 100.0 | 3.937 | 33.0 | 1.299 | 35.0 | 1.378 | 14.0 | 0.551 |

| CCB4 125/45 | 125.0 | 4.921 | 47.0 | 1.850 | 45.0 | 1.772 | 22.0 | 0.866 |

CCB5 – Five Core Breakouts

| Order Number | Breakout Main Diameter | Finger Diameter | ||||||

| Min | Max | Min | Max | |||||

| mm | in | mm | in | mm | in | mm | in | |

| CCB5 80/26 | 80.0 | 3.150 | 30.0 | 1.181 | 26.0 | 1.024 | 7.5 | 0.295 |

| CCB5 100/34 | 100.0 | 3.937 | 33.0 | 1.299 | 34.0 | 1.339 | 9.0 | 0.354 |

CCB6 – Six Core Breakouts

| Order Number | Breakout Main Diameter | Finger Diameter | ||||||

| Min | Max | Min | Max | |||||

| mm | in | mm | in | mm | in | mm | in | |

| CCB6 85/25 | 85.0 | 3.346 | 35.0 | 1.378 | 25.0 | 0.984 | 6.0 | 0.236 |

Subject to technical changes