CPX 876 – Americas

Thin wall highly flame retardant crosslinked polyolefin

Features and Benefits

- Highly flame retardant for use in consumer products

- Low shrink temperature reduces risk of damage to electronic components

- Flexible

- Resistant to common fluids and solvents

- Printable

- Shrink ratio: 2:1

- Continuous operating temperature: -55°C to 135°C

- Shrink temperature: 85°C

Standards

- UL 224 125C VW-1 – UL file # E107857

- CSA 22.2 No 198.1 125C OFT and Class 1 – CSA file # 265111

- DEF STAN 59-97, Issue 3 Type 1a

Typical Applications

Strain relief of wire connections, insulation of in-line splices, protection and bundling of small harnesses

Market/Applications

- OEM

- Aerospace Defense

Ordering

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Black (BK), Red (RD), White (WT), Blue (BL), Yellow (YL), Green (GR)

- Printing: Printed or unprinted

- Length: Continuous reels

- Please specify the product name, order number and options you require

- Order Example: CPX 876, 0125, black, unprinted, 1,000 ft lengths

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

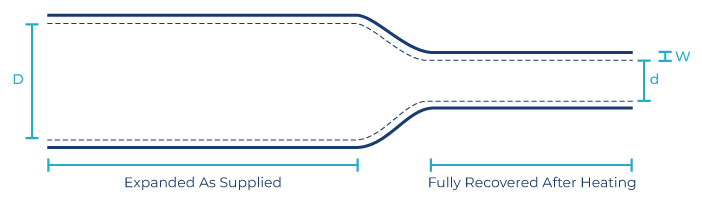

| Order Number | Expanded | Recovered | Lengths | |||||

| Internal Diameter (Min) D |

Internal Diameter (Max) d |

Wall Thickness (Nom) W |

||||||

| mm | in | mm | in | mm | in | m | ft | |

| 0047 | 1.2 | 3/64 | 0.6 | 3/128 | 0.45 | 0.018 | 300 | 1,000 |

| 0062 | 1.6 | 1/16 | 0.8 | 1/32 | 0.45 | 0.018 | 300 | 1,000 |

| 0093 | 2.4 | 3/32 | 1.2 | 3/64 | 0.51 | 0.020 | 300 | 1,000 |

| 0125 | 3.2 | 1/8 | 1.6 | 1/16 | 0.51 | 0.020 | 300 | 1,000 |

| 0187 | 4.8 | 3/16 | 2.4 | 3/32 | 0.51 | 0.020 | 300 | 1,000 |

| 0250 | 6.4 | 1/4 | 3.2 | 1/8 | 0.64 | 0.025 | 150 | 500 |

| 0375 | 9.5 | 3/8 | 4.8 | 3/16 | 0.64 | 0.025 | 150 | 500 |

| 0500 | 12.7 | 1/2 | 6.4 | 1/4 | 0.64 | 0.025 | 60 | 200 |

| 0625 | 16.0 | 5/8 | 8.0 | 5/16 | 0.64 | 0.030 | 60 | 200 |

| 0750 | 19.0 | 3/4 | 9.5 | 3/8 | 0.76 | 0.030 | 30 | 100 |

| 1000 | 25.4 | 1 | 12.7 | 1/2 | 0.89 | 0.035 | 30 | 100 |

| 1250 | 32.0 | 1 ¼ | 16.0 | 5/8 | 0.89 | 0.040 | 30 | 100 |

| 1500 | 38.1 | 1 ½ | 19.0 | 3/4 | 1.02 | 0.040 | 30 | 100 |

| 2000 | 50.8 | 2 | 25.4 | 1 | 1.14 | 0.060 | 30 | 100 |

| 3000 | 76.2 | 3 | 38.1 | 1 ½ | 1.27 | 0.060 | 15 | 50 |

| 4000 | 101.6 | 4 | 50.8 | 2 | 1.40 | 0.060 | 15 | 50 |