DMS NH

Halogen free heat shrink identification sleeve

Zero halogen & low smoke heat shrink identification sleeve. The product complies with the stringent requirements of the European rail norm EN45545-2 and the HL3 R22/R23 classification and even over exceeds those. The material is suitable for use in all classes required for the construction of locomotives and rolling stock. It is also suitable for use in underground environments as well as marine, military and aerospace applications.

Features and Benefits

- Low smoke generation – excellent fire safety characteristics

- Emissions of toxic fumes are well below the levels required to meet the relevant standards

- Special packing enables immediate installation on the application

- Flexible

- Flame retardant

- Good fluid resistance

- Soft surface finish supports good printability

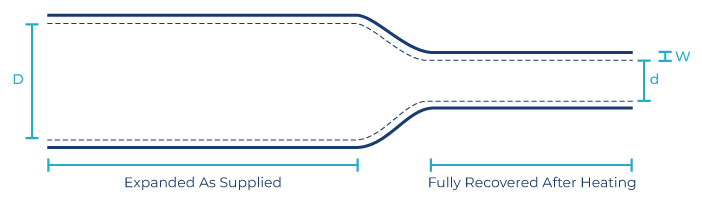

- Shrink ratio: 2:1

- Continuous operating temperature: -40°C to 125°C

- Shrink Temperature: 120°C min.

Standards

- EN45545-2 HL3 R22/R23

- Meets LUL E 1042 A6

- BS 6853 vehicle category 1a

- DIN 5510

- EN 50343*

- SAE AS81531 4.6.2*

- MIL-STD-202G Method215*

- NFPA 130

*Hardware used “XD Q” printer from CAB and “RBZ11DR” ribbon from DSG-Canusa.

Typical Applications

Cable identification

Market/Applications

- Mass Transit

- Subways

- Defense

- Aerospace

- Offshore

- Marine

- Industrial

Ordering

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Yellow (YW), White (WT)

- Perforation: no perforation (P0), 1 perforation (P1), 2 perforations (P2), 3 perforations (P3)

- Please specify the product name, order number and options you require

- Order example: DMS NH, P1, 4.8, yellow, 1,000 pieces

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Delivery Units | Recommended Cable Diameter | ||||

| Internal Diameter (Min) D |

Internal Diameter (Max) d |

Wall Thickness (Nom) W |

Pieces per reel | |||||

| mm | in | mm | in | mm | in | mm (in) | ||

| DMS NH 2.4 | 2.4 | 3/32 | 1.2 | 3/64 | 0.51 | 0.020 | 2,500 | 0,64 – 1,83 (0,025 – 0,072) |

| DMS NH 3.2 | 3.2 | 1/8 | 1.6 | 1/16 | 0.51 | 0.020 | 2,500 | 1,02 – 2,59 (0,040 – 0,102) |

| DMS NH 4.8 | 4.8 | 3/16 | 2.4 | 3/32 | 0.51 | 0.020 | 1,000 | 1,63 – 4,12 (0,064 – 0,162) |

| DMS NH 6.4 | 6.4 | 1/4 | 3.2 | 1/8 | 0.64 | 0.025 | 1,000 | 2,59 – 5,82 (0,102 – 0,229) |

| DMS NH 9.5 | 9.5 | 3/8 | 4.8 | 3/16 | 0.64 | 0.025 | 1,000 | 4,12 – 8,25 (0,162 – 0,325) |

| DMS NH 12.7 | 12.7 | 1/2 | 6.4 | 1/4 | 0.64 | 0.025 | 500 | 5,20 – 10,80 (0,205 – 0,425) |

| DMS NH 19.0 | 19.0 | 3/4 | 9.5 | 3/8 | 0.76 | 0.030 | 500 | 6,80 – 16,10 (0,268 – 0,634) |

| DMS NH 25.4 | 25.4 | 1 | 12.7 | 1/2 | 0.89 | 0.035 | 500 | 8,80 – 21,20 (0,346 – 0,835) |

| DMS NH 38.1 | 38.1 | 1 1/2 | 19.0 | 3/4 | 1.02 | 0.040 | 500 | 12,60 – 34,20 (0,496 – 1,346) |