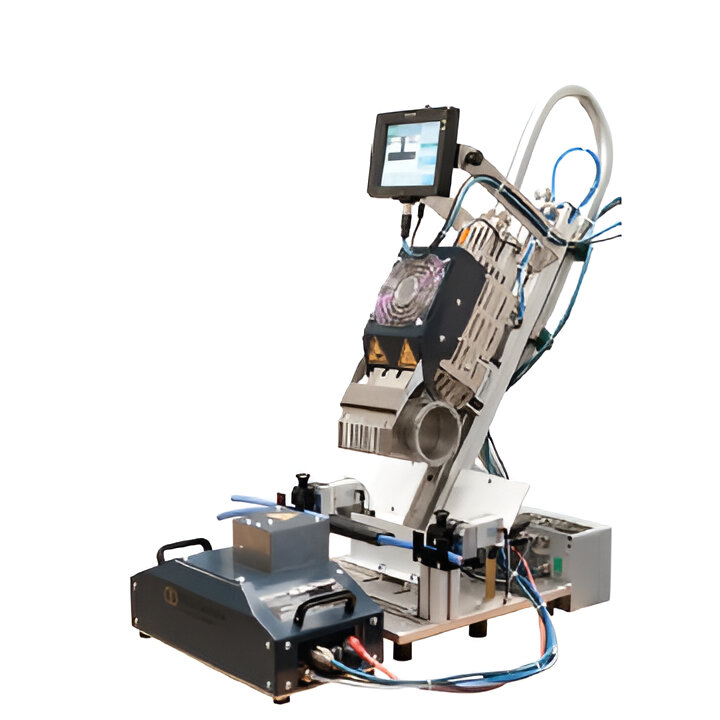

DERAY®-Vision System

The Vision System is a camera-based inspection system as a plug & play add-on for DERAY®-WorkMan 2.0. It is designed to control visual characteristics of any application like positioning of the heat shrink sleeve and the application, colours of wires and several more. The Vision System is able to control up to 16 different characteristics per monitoring step. Customer can configure a variable number of test sequences of each process.

Features and Benefits

- Application specific requirement setting via touch panel

- Automatic visual feedback of error messages in the process

- Customized fixation and locking mount for process safety according to poka-yoke principles

- Security lock of defective parts on operator level

- Picture backup of each visual feedback for traceability purposes

- Additional camera accessories for best possible visual inspection

- Communication systems: Profi Net (TCP/IP) via DERAY®-WorkMan 2.0

- Selection of system language: English, German, French, Spanish (others on demand)

- CE and RoHs conformance

- CHECK Testing

Applications

Terminals, Y- Splices for HV, parallel and end splices, applications where visual aspects need to be monitored

Operation

DERAY®-Vision System is mounted to the DERAY®-WorkMan 2.0 which can be taught to control and monitor certain visual aspects of specific applications. To ensure continuous and safe produced parts, the DERAY®-Vision System starts the shrinking process only after all initially set parameters are detected as OK, then by camera moving out of the base section of the equipment. Additionally a visual control after shrinking can be integrated to double check if all characteristics are met. Each scanning process only takes a few second which eliminates any process downtime.

Order Information

DERAY®-Vision System

Heat-shrink products & sizes:

DSG-Canusa heat shrink products:

- with lengths of up to 120 mm

- CCB Divider Cap

For other products and sizes contact DSG-Canusa Application Engineering.

Scope of Delivery:

- Control unit

- Vision system

- Display for monitoring and set up incl. mount

- Operating manual: DE, EN, FR, ES (others on demand)

Accessories:

- Memory extension for picture backup

- Background for difficult shade detection

- Polarization filter

- Dome light attachment

Technical data

| Properties | |

| Electrical connection | 1/N/PE AC 230 V 50-60 Hz |

| Electrical current consumption | Approx. 1.1 kW/h at 275 °C shrink temperature |

| Electrical power consumption | Max. 3.6 kW |

| Rated current | 16 A |

| Elec. fuse protection at the owner | 16 A |

| Degree of protection | Control unit: IP 54; Head: IP 20 |

| Shrink temperature | 150 °C – 300 °C (302 °F – 572 °F) |

| Pneumatic connection | 6 – 8 bar (90 – 115 psi) |

| Pneumatic work pressure | 5 bar (72 psi) |

| Compressed air consumption | 100 – 300 ltr/min (3.5 – 10.6 cfm) |

| Heating air shrink chamber adj. | 0.5 – 1.0 bar (7.3 – 14.5 psi) |

| Ambient temperature | 10 °C – 45 °C (50 °F – 113 °F) |

| Sound pressure level | Approx. 67 dB(A) |

| Dimensions and weight | |

| Shrink equipment | w 400 x h 770 x d 570 mm (w 15.7 x h 30.3 x d 22.4 in), 18 kg (39.7 lbs) |

| Control unit | w 400 x h 480 x d 340 mm (w 15.7 x h 18.9 x d 13.4 in), 19 kg (41.9 lbs) |

| Vision system | w 400 x h 190 x d 270 mm (w 15.7 x h 7.5 x d 10.6 in), 4 kg (8.8 lbs) |