Heat-shrink machines and equipment by DSG-Canusa

Heat shrink-machines and heat shrink-equipment: in-house design made in Germany

Our DSG-Canusa Machine Technology Center (MTC) designs and manufactures both standard and customized shrink and inspection systems, to assemble and test heat-shrink applications. Engineering and manufacturing are located in the same facility, giving us the opportunity to develop high-quality heat-shrink machines, such as infrared technology equipment and hot air machines, as well as machines for testing purposes, for example, leakage testing. Providing both heat-shrink products and heat-shrink equipment makes us unique in the market. A full-service package of support before, during and after the introduction of one of our heat-shrink machines is a customer favorite. Our devices feature state-of-...Heat shrink-machines and heat shrink-equipment: in-house design made in Germany

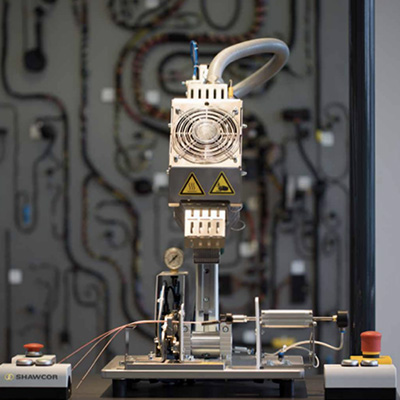

Our DSG-Canusa Machine Technology Center (MTC) designs and manufactures both standard and customized shrink and inspection systems, to assemble and test heat-shrink applications. Engineering and manufacturing are located in the same facility, giving us the opportunity to develop high-quality heat-shrink machines, such as infrared technology equipment and hot air machines, as well as machines for testing purposes, for example, leakage testing. Providing both heat-shrink products and heat-shrink equipment makes us unique in the market. A full-service package of support before, during and after the introduction of one of our heat-shrink machines is a customer favorite. Our devices feature state-of-the-art designs that enable continuous improvement of shrink temperatures and times, a high level of operator convenience and automation, and maximum production efficiency. These high-quality attributes apply to our hot-air-based equipment, our infrared technologies and all components. In addition to the fulfilment of basic functions, we focus on high-level monitoring and continuous improvement. At the Rheinbach, Germany facility, our engineers and customers work together to develop new and different types of heat-shrink machines and shrink tunnel machines that offer superior technical performance and withstand the mechanical stresses of everyday use. Our application engineers excel at innovations that are highly flexible and efficient. By working closely with our customers, we can create solutions tailored to their needs and also support their projects from the initial use through their application's standard operating procedure and beyond. Our portfolio includes several heat-shrink machines and technologies, some examples of which are viewable on our website; we also offer fully customized solutions. Please reach out to our team to discuss your needs so that you and DSG-Canusa can build the future together. Standard features available on our appliances:- High quality and constant heat distribution for continuous reproducibility

- Modular plug and play options allow for device upgrades (instead of procuring new ones), resulting in cost efficiency and sustainability

- Poka-Yoke designed process (by software and hardware) to minimize operator influence

- Camera-based inspection systems for 100% process safety

- Full digital integration of our devices into your Manufacturing Execution System (MES)

Categories:

- Single Wall Tubing

- Dual Wall Tubing

- Medium and Heavy Wall Tubing

- High Temperature Products

- Marker Sleeves

- Braided Sleeves

- Halogen-Free Heat-Shrink Tubing

- Wildlife Mitigation

- Protection Caps

- Electrical Products

- Electrical Connection Systems

- Heat-Shrink Machines

- Water Blocking Solutions

- Market Specific Solutions

Filter by:

-

DERAY®-ACIS

View Product: DERAY®-ACIS

DERAY®-ACIS

The DERAY®-ACIS is an extension to enable the entire system for 100% accuracy of the centered heat shrink sleeve positioning in accordance to the splice welding spot. For additional process safety the DERAY®-ACIS is able to monitor several parameters like, sleeve length and wire bundle diameter for additional quality inspection. Furthermore the DERAY®-ACIS is ensuring a maximal efficiency of cycle time due to it’s semi continuous feeding were shrinking, colling and centering are processed simultaneal.

MORE DETAILS -

DERAY®-ACIS+

View Product: DERAY®-ACIS+

DERAY®-ACIS+

The DERAY®-ACIS is an extension to enable the entire system for 100% accuracy of splice conductor and heat shrink sleeve off-center positioning in a balanced and as well unbalanced splice configuration in correlation to the wire bundle diameter difference. For additional process safety the DERAY®-ACIS is able to monitor several parameters like, sleeve length, sleeve diameter for additional quality inspection of the used heat shrink sleeve and conductor length to verify correct welding / strip lengths.

MORE DETAILS -

DERAY®-ACP-V

View Product: DERAY®-ACP-V

DERAY®-ACP-V

Circulating hot air shrink equipment

The DERAY-ACP-V is a circulating hot air shrink equipment with automatic collision detection designed to process single wall heat shrink tubes onto cables.

MORE DETAILS -

DERAY®-Board-WorkMan RFID

View Product: DERAY®-Board-WorkMan RFID

DERAY®-Board-WorkMan RFID

Mobile shrink equipment

DERAY-Board-Workman RFID is a mobile shrink equipment designed to process heat shrink tubes onto splices and multicore cable sets for longitudinal water sealing on the harness board.

MORE DETAILS -

DERAY®-Board-WorkMan TP ADE

View Product: DERAY®-Board-WorkMan TP ADE

DERAY®-Board-WorkMan TP ADE

Mobile shrink equipment with outer diameter detector

DERAY-Board-Workman TP ADE is a mobile shrink equipment with outer diameter detector (ADE) which is used on the harness board with a balancer.

MORE DETAILS -

DERAY®-DockMan Junior Endsplice

View Product: DERAY®-DockMan Junior Endsplice

DERAY®-DockMan Junior Endsplice

Hot air shrink equipment

The DERAY-DockMan Junior Endsplice is a hot air shrink equipment to process heat shrink tubes in wiring systems. It is primarily used for mobile, manual use on the cable board with a balancer.

MORE DETAILS -

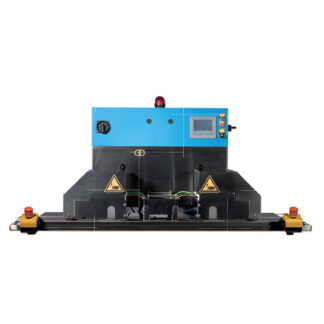

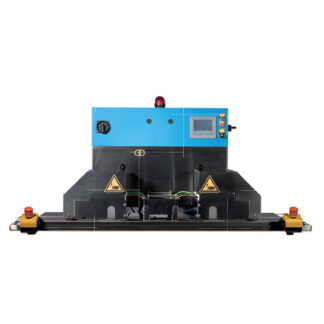

DERAY®-FST 950 2.0

View Product: DERAY®-FST 950 2.0

DERAY®-FST 950 2.0

New generation belt driven shrink tunnel

The DERAY-FST 950 2.0 is a semi-automatic shrink tunnel with infrared heating elements designed to process a wide variety of heat shrink products for safe high volume production.

MORE DETAILS -

DERAY®-Leakage Tester

View Product: DERAY®-Leakage Tester

DERAY®-Leakage Tester

Leakage tester

The DERAY-Leakage Tester is a testing device designed for the leaking test of wire applications assembled with heat shrink tubes. Using compressed air and four test chambers it can leakage test up to 20 cables.

MORE DETAILS -

DERAY®-Mini Shrink Device 2.0

View Product: DERAY®-Mini Shrink Device 2.0

DERAY®-Mini Shrink Device 2.0

The DERAY®-Mini Shrink Device 2.0 is a lean heatshrink system with infrared heating elements designed to process heat-shrink tubes onto ultrasonically welded- and crimped splice joints.

MORE DETAILS -

DERAY®-Proof

View Product: DERAY®-Proof

DERAY®-Proof

Manual testing equipment

The DERAY-Proof is a manually operated pneumatic testing equipment to check splice joints and various terminals fitted with adhesive lined heat shrink tubes for leaks.

MORE DETAILS -

DERAY®-PSP 240-S

View Product: DERAY®-PSP 240-S

DERAY®-PSP 240-S

Heat shrink system for splice sealing products

The DERAY-PSP 240-S is a heat shrink system designed to process adhesive lined heat shrink tubes on splice joints in batches of 5.

MORE DETAILS -

DERAY®-PSP-D

View Product: DERAY®-PSP-D

DERAY®-PSP-D

Heat shrink system

The DERAY-PSP-D is a heat shrink system with infrared heating elements designed to process adhesive lined heat shrink tubes onto splice joints, especially for twisted cables, in batches of 5.

MORE DETAILS