CPA 100

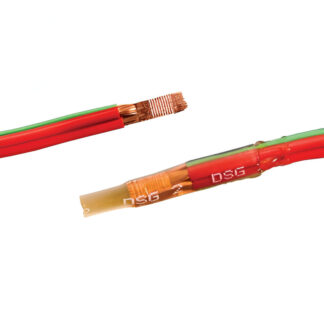

Thin wall adhesive lined crosslinked polyolefin

Adhesive lined heat shrink tubing with environmental sealing capability ideal for a variety of applications including general purpose automotive and marine wire harness bundles, industrial splices, breakouts and connector to cable transitions

Features and Benefits

- Superior sealing against water, moisture or other contaminants

- High shrink ratio allows for coverage of irregularly shaped connectors and components

- Inner adhesive bonds to plastics, rubber, neoprene, steel and polyethylene

- Rated for 1 kV, 90°C continuous use

- Shrink ratio: 3:1

- Continuous operating temperature: -55°C to 110°C

- Shrink temperature: 90°C

Typical Applications

Environmental sealing and strain relief of connectors and terminals, moisture sealing and electrical insulation of simple in-line splices, abrasion resistance for tubes and pipes, repair of damaged wire harnesses

Market/Applications

- Dual Wall

- Industrial

- Automotive

Ordering

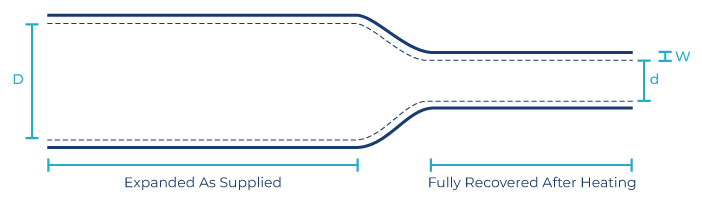

- Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Black (BK), Red (RD), Clear (CL), Blue (BL), White (WT), Yellow (YW)

- Length: Standard Stick, Spool or custom length

- Please specify the product name, order number and options you require

- Order Example: CPA 100, 0125, black, 48 in lengths

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Lengths (Sticks) | |||||||

| Internal Diameter (Min) D | Internal Diameter (Max) d | Total Wall Thickness (Nom) W | Meltable Wall Thickness (Nom) | |||||||

| mm | in | mm | in | mm | in | mm | in | m | in | |

| 0125 | 3.2 | 1/8 | 1.0 | 0.040 | 1.0 | 0.040 | 0.5 | 0.020 | 1.2 | 48 |

| 0187 | 4.7 | 3/16 | 1.5 | 0.060 | 1.0 | 0.040 | 0.5 | 0.020 | 1.2 | 48 |

| 0250 | 6.4 | 1/4 | 2.0 | 0.080 | 1.0 | 0.040 | 0.5 | 0.020 | 1.2 | 48 |

| 0312 | 7.9 | 5/16 | 2.5 | 0.100 | 1.3 | 0.050 | 0.7 | 0.027 | 1.2 | 48 |

| 0375 | 9.5 | 3/8 | 3.2 | 0.125 | 1.5 | 0.060 | 0.7 | 0.027 | 1.2 | 48 |

| 0500 | 12.7 | 1/2 | 4.1 | 0.160 | 1.8 | 0.070 | 0.8 | 0.030 | 1.2 | 48 |

| 0750 | 19.1 | 3/4 | 6.4 | 0.250 | 1.8 | 0.070 | 0.8 | 0.030 | 1.2 | 48 |

| 1000 | 25.4 | 1 | 8.1 | 0.320 | 2.5 | 0.100 | 1.0 | 0.040 | 1.2 | 48 |

| 1250 | 31.8 | 1 ¼ | 10.6 | 0.416 | 2.5 | 0.100 | 1.0 | 0.040 | 1.2 | 48 |

| 1500 | 39.9 | 1 ½ | 13.0 | 0.510 | 2.5 | 0.100 | 1.0 | 0.040 | 1.2 | 48 |