DERAY®-Board-WorkMan TP ADE

Mobile shrink equipment with outer diameter detector

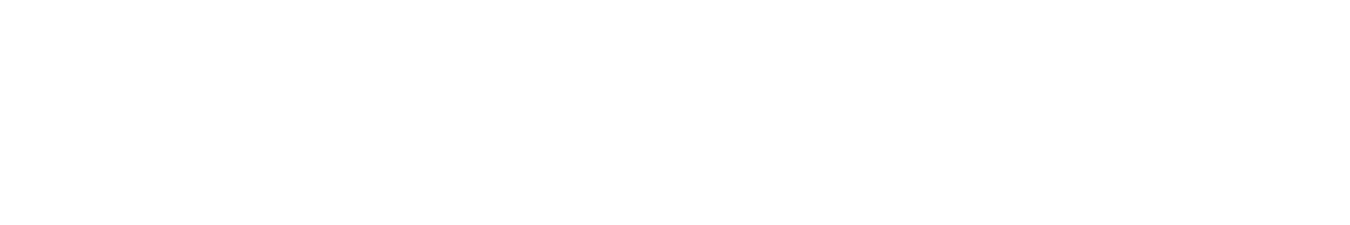

DERAY®-Board-Workman TP ADE is a mobile shrink equipment with outer diameter detector (ADE) which is used on the harness board with a balancer. It is designed to process adhesive lined heat shrink tubes onto end splices on stationary and mobile cable boards.

Features and Benefits

- Mobile use on the cable wire board

- Automatic outside diameter detection of wires and allocation of shrink parameters

- High application variety through various shrink chamber sizes

- Quick-change system of shrink chambers for minimal process interruption

- Simple and easy handling via Siemens Touch Panel

- Automatic selection of process parameters via USB scanner or manually via touch panel

- Adjustable parameters: Shrink and cooling time, temperature control through Siemens CPU

- Password protected programming mode

- Communication systems: RS232, TCP/IP and OPC UA

- Day cycle counter and total cycle counter

- Selection of system language: English, German, Spanish (others on demand)

- CE and RoHs conformity

Applications

End splices on wiring harness boards

Operation

The DERAY®-Brett-WorkMan TP ADE has an object holder for inserting an end splice by hand. The process parameters are automatically loaded from the CPU by the outer diameter detection (ADE), depending on the wire cross section. Once the shrink equipment is docked to the cable forming board, the shrink process is started and the heating unit moves into working position. After the cycle time (shrink time + cooling time) is finished, the heating unit moves back to its home position and the processing unit can be docked to the next workstation.

Order Information

DERAY®-Board-Workman TP ADE

Heat Shrink Prouducts & Sizes

- DERAY®-SpliceMelt Cap Sizes 1 to 4, length max. 70 mm

For other products and sizes contact DSG-Canusa Application Engineering

Scope of Delivery

- Shrink equipment

- Control unit

- External stop button

- Balancer

- One shrink chamber

- Operating manual: German, Spanish (others on demand)

Accessories

- Shrink chambers: Widths 24 – 36 – 48 – 60 mm; internal diameter 30 – 45 mm

- USB scanner

Market/Applications

- Dual Wall

- Single Wall

- OEM

- Splice Sealing Solutions

- Automotive

- Application Equipment

- Waterblocking

| Properties | |

| Electrical connection | 1/N/PE AC 230 V 50-60Hz |

| Electrical power consumption | approx. 1.1 kW/h at 275°C shrink temperature |

| Electrical power consumption | max. 3.6kW |

| Rated current | 16A |

| Electrical fuse protection at the owner | 16A |

| Degree of protection of control unit | IP54 |

| Degree of protection of shrink head | IP20 |

| Shrink temperature | 150°C – 275°C (302°F – 527°F) |

| Pneumatic connection | 6 – 10 bar (87 – 145 psi) |

| Pneumatic work pressure | 5 bar (72psi) |

| Air consumption | 150 bis 180 ltr/min. (5.3 – 6.4 cfm) |

| Length corrugated pipe connecting hose | 15 m (49 ft) |

| Ambient temperature | 10°C – 45°C (50°F – 113°F) |

| Sound pressure level | approx. 67 dB(A) |

| Dimensions and weight | |

| Shrinking machine | w 600 x h 400 x d 330 mm (w 27.6 x h 15.7 x d 13 in) 20 kg (44 lbs) |

| Control unit | w 420 x h 220 x d 800 mm (w 16.5 x h 8.6 x d 31.5 in) 18 kg (39.6 lbs) |