DERAY®-KYF 190

Flexible thin wall Kynar®

High temperature Kynar® thin wall heat shrink tubing, with extreme chemical resistance ideal for protection of components in a wide range of severe temperature and harsh environments.

Features and Benefits

- Highly flame retardant

- Flexible

- High temperature resistance

- Excellent chemical and solvent resistance

- Shrink ratio: 2:1

- Continuous operating temperature: -55°C to 190°C

- Shrink temperature: 175°C

Standards

- VW 60360-3

- UL 224 125C VW-1 – UL file # E132910

- CSA 22.2 No 198.1 125C – CSA file # 065789_0_000

- QPL SAE AS23053/18 Class 2

- CNES approved and listed in Matrex database

- ECSS-Q-ST-70-02

Typical Applications

High temperature performance that meets or exceeds military, industrial and automotive standards, provides excellent electrical insulation, high flexible and abrasion resistance requiring applications, protective see through covering for high temperature and aggressive chemical applications, protecting component for connectors and HV cable-lugs in electric vehicles

Market/Applications

- Automotive

- Industrial

- Defense

- Aerospace

- Mass Transit

Ordering

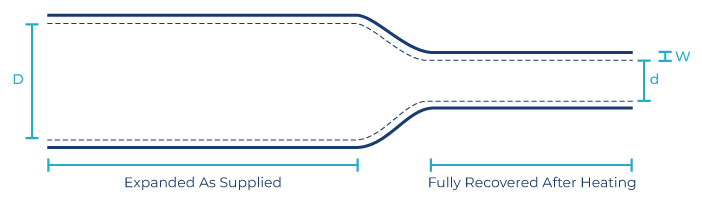

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Clear (CL), black (BK) & orange (OE) against MOQ

- Approval: Standard or QPL

- Please specify the product name, order number and options you require

- Order example: DERAY®-KYF 190, 0125 or 1/8in, clear, QPL

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Delivery Units | ||||||

| Internal Diameter (Min) D |

Internal Diameter (Max) d |

Wall Thickness (Nom) W |

Spool* | Lengths 1.22m / 48in |

|||||

| mm | in | mm | in | mm | in | m | ft | pcs | |

| 0047 | 1.2 | 3/64 | 0.6 | 0.024 | 0.24 | 0.009 | 300 | 984 | 25 |

| 0063 | 1.6 | 1/16 | 0.8 | 0.031 | 0.24 | 0.009 | 300 | 984 | 25 |

| 0094 | 2.4 | 3/32 | 1.2 | 0.047 | 0.24 | 0.009 | 300 | 984 | 25 |

| 0125 | 3.2 | 1/8 | 1.6 | 0.063 | 0.24 | 0.009 | 300 | 984 | 25 |

| 0187 | 4.8 | 3/16 | 2.4 | 0.094 | 0.24 | 0.009 | 300 | 984 | 25 |

| 0250 | 6.4 | 1/4 | 3.2 | 0.126 | 0.30 | 0.012 | 300 | 984 | 10 |

| 0375 | 9.5 | 3/8 | 4.8 | 0.189 | 0.30 | 0.012 | 150 | 492 | 10 |

| 0500 | 12.7 | 1/2 | 6.4 | 0.252 | 0.30 | 0.012 | 100 | 328 | 10 |

| 0591* | 15.0 | 0.591 | 6.4 | 0.252 | 0.80 | 0.031 | 100 | 328 | – |

| 0750 | 19.0 | 3/4 | 9.5 | 0.374 | 0.40 | 0.016 | 100 | 328 | – |

| 1000 | 25.4 | 1 | 12.7 | 0.500 | 0.50 | 0.020 | 50 | 164 | – |

| 1500 | 38.1 | 1½ | 19.0 | 0.748 | 0.60 | 0.024 | 50 | 164 | – |

*Size 0591 in black and clear against MOQ