CPX 100

Thin wall crosslinked polyolefin

Flexible, multi-purpose heat shrink tubing

Features and Benefits

- Flame retardant (colors only)

- Resistant to common fluids and solvents

- All Colors Except clear or transparent tubing are UV resistant

- Economical mechanical protection for terminal strain relief and wire bundling

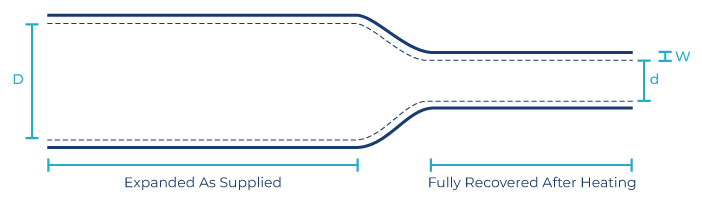

- Shrink ratio: 2:1

- Continuous operating temperature: -55°C to 135°C

- Shrink temperature: 90°C

Standards

- UL 224 (600 volts, 125°C) – UL file # YDPU2.E63390 (Black and Colors only)

- CSA C22.2 No. 198.1, 125°C – CSA file # 256317 & 065781_0_000

- SAE-AMS-DTL-23053/5, Class 1 and 2

- UL/CSA approval applies to Black and colors only

- Approved to major automotive OEM specifications

Typical Applications

Electrical insulation of wire splices and terminals, strain relief of wire terminations, protects components from abrasion and fluids

Market/Applications

- Single Wall

- Automotive

Ordering

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Black (BK), Red (RD), White (WT), Clear (CL), Blue (BL), Yellow (YL), Green (GR)

- Size 5000 available only in Black (BK)

- Length: Standard Stick, Spool or custom length

- Please specify the product name, order number and options you require

- Order Example: CPX 100, 0375, black, 500 ft

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Lengths | |||||

| Internal Diameter (Min) D | Internal Diameter (Max) d | Wall Thickness (Nom) W | ||||||

| mm | in | mm | in | mm | in | m | ft | |

| 0047 | 1.2 | 3/64 | 0.6 | 3/128 | 0.41 | 0.016 | 300 | 1000 |

| 0063 | 1.6 | 1/16 | 0.8 | 1/32 | 0.43 | 0.017 | 300 | 1000 |

| 0094 | 2.4 | 3/32 | 1.2 | 3/64 | 0.51 | 0.020 | 300 | 1000 |

| 0125 | 3.2 | 1/8 | 1.6 | 1/16 | 0.51 | 0.020 | 300 | 1000 |

| 0187 | 4.8 | 3/16 | 2.4 | 3/32 | 0.51 | 0.020 | 300 | 1000 |

| 0250 | 6.4 | 1/4 | 3.2 | 1/8 | 0.64 | 0.025 | 150 | 500 |

| 0375 | 9.5 | 3/8 | 4.7 | 3/16 | 0.64 | 0.025 | 150 | 500 |

| 0500 | 12.7 | 1/2 | 6.4 | 1/4 | 0.64 | 0.025 | 60 | 200 |

| 0625 | 16.0 | 5/8 | 8.0 | 5/16 | 0.76 | 0.030 | 60 | 200 |

| 0750 | 19.0 | 3/4 | 9.5 | 3/8 | 0.76 | 0.030 | 30 | 100 |

| 1000 | 25.4 | 1 | 12.7 | 1/2 | 0.89 | 0.035 | 30 | 100 |

| 1250 | 32.0 | 1 ¼ | 16.0 | 5/8 | 0.89 | 0.035 | 30 | 100 |

| 1500 | 38.1 | 1 ½ | 19.0 | 3/4 | 1.02 | 0.040 | 30 | 100 |

| 2000 | 50.8 | 2 | 25.4 | 1 | 1.14 | 0.045 | 30 | 100 |

| 3000 | 76.2 | 3 | 38.0 | 1 ½ | 1.27 | 0.050 | 15 | 50 |

| 4000 | 101.6 | 4 | 50.8 | 2 | 1.40 | 0.055 | 15 | 50 |

| 5000 | 125.0 | 5 | 62.50 | 2 ½ | 1.40 | 0.055 | 15 | 50 |