CBTM – EMEA

Medium voltage crosslinked polyolefin bus bar tubing

Medium wall anti-track heat shrinkable tubing specially designed for insulating medium voltage bus bars.

Features and Benefits

- Halogen free and flame retardant

- Reduces bus bar clearance requirements

- Protects against accidental flashover

- Anti-track

- CBTM medium wall tubing rated to 25 kV

- Shrink ratio: 3:1

- Continuous operating temperature: -40°C to 125°C

- Shrink temperature: 120°C

Standards

- ANSI C37.20.2

- ANSI C37.20.3

- UL file #E205844

Typical Applications

Insulation of medium voltage bus bars in switchgear equipment, transformers and generators

Market/Applications

- OEM

- Power Distribution

- Industrial

- Power Distribution – MV

- Utility

Ordering

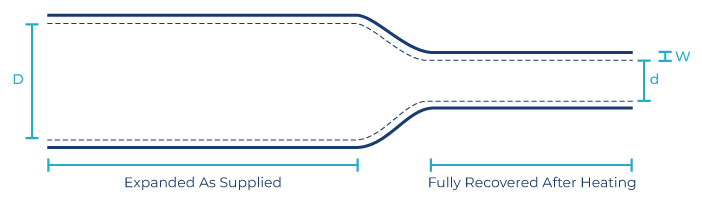

Select a dimension which will shrink snugly over the component to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Red (RD)

- Please specify the product name, order number and options you require

- Order example: CBTM 2050, red or CBTM 76/30, red

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Delivery Units | |||||

| Internal Diameter (Min) D |

Internal Diameter (Max) d |

Total Wall Thickness (Nom) W |

Lengths | |||||

| mm | in | mm | in | mm | in | m | ft | |

| 0750 | 19.0 | 0.748 | 5.5 | 0.217 | 2.70 | 0.106 | 15.24 | 50 |

| 1300 | 33.0 | 1.299 | 10.1 | 0.398 | 3.00 | 0.118 | 15.24 | 50 |

| 2050 | 52.0 | 2.047 | 19.0 | 0.748 | 2.80 | 0.110 | 15.24 | 50 |

| 2750 | 69.8 | 2.748 | 25.4 | 1.000 | 2.90 | 0.114 | 15.24 | 50 |

| 3500 | 88.9 | 3.500 | 29.9 | 1.177 | 3.10 | 0.122 | 15.24 | 50 |

| 4700 | 119.3 | 4.697 | 39.9 | 1.571 | 3.20 | 0.126 | 15.24 | 50 |

| 6700 | 170.1 | 6.697 | 58.4 | 2.999 | 3.20 | 0.126 | 15.24 | 50 |

| Metric Dimensions | ||||||||

| 19/6 | 19.0 | 0.748 | 6.0 | 0.236 | 2.00 | 0.079 | 50.00 | 164 |

| 33/10 | 33.0 | 1.299 | 10.0 | 0.394 | 2.50 | 0.098 | 50.00 | 164 |

| 52/19 | 52.0 | 2.047 | 19.0 | 0.748 | 2.50 | 0.098 | 25.00 | 82 |

| 76/30 | 76.0 | 2.992 | 30.0 | 1.181 | 2.50 | 0.098 | 15.00 | 49 |

| 100/40 | 100.0 | 3.937 | 40.0 | 1.575 | 2.50 | 0.098 | 15.00 | 49 |

| Application Ranges | ||||||

| Order Number | Rectangular Bus Bars | Round Bus Bars | ||||

| Min | Max | Min – Max | ||||

| mm | in | mm | in | mm | in | |

| 0750 and 19/6 | 6.4 x 6.4 | 0.252 x 0.252 | 6.4 x 15.9 | 0.252 x 0.626 | 6.8 – 15.2 | 0.268 – 0.598 |

| 1300 and 33/10 | 12.7 x 6.4 | 0.500 x 0.252 | 28.5 x 15.9 | 1.122 x 0.626 | 12.4 – 27.9 | 0.488 – 1.098 |

| 2050 and 52/19 | 31.5 x 6.4 | 1.240 x 0.252 | 50.8 x 15.9 | 2.000 x 0.626 | 22.3 – 43.1 | 0.878 – 1.697 |

| 2750 | 44.4 x 6.4 | 1.748 x 0.252 | 76.2 x 15.9 | 3.000 x 0.626 | 29.7 – 58.4 | 1.169 – 2.299 |

| 76/30 | 63.9 x 6.4 | 2.520 x 0.252 | 90.1 x 15.9 | 3.547 x 0.626 | 45.0 – 68.0 | 1.772 – 2.677 |

| 3500 | 57.1 x 6.4 | 2.248 x 0.252 | 101.6 x 15.9 | 4.000 x 0.626 | 35.8 – 73.6 | 1.409 – 2.898 |

| 100/40 | 103.6 x 6.4 | 4.079 x 0.252 | 114.1 x 15.9 | 4.492 x 0.626 | 70.0 – 83.0 | 2.756 – 3.268 |

| 4700 | 73.0 x 6.4 | 2.874 x 0.252 | 142.8 x 15.9 | 5.622 x 0.626 | 47.7 – 101.6 | 1.878 – 4.000 |

| 6700 | 114.3 x 6.4 | 4.500 x 0.252 | 203.2 x 15.9 | 8.000 x 0.626 | 69.5 – 144.7 | 2.736 – 5.697 |

Application ranges noted above selected to obtain minimum insulation thickness required to meet ANSI C37.20.2 withstands requirements at bus bar spacing noted below. These spacings were determined from a limited number of test configurations. Due to the wide variety of bus bar configurations, these spacings should not be employed without actual testing by the user.

Clearances with Insulation

| System Voltage | BIL kV | CBTM Medium Wall Tubing | |||

| P to P | P to G | ||||

| mm | in | mm | in | ||

| 15 kV | 95.0 | 86.0 | 3.386 | 106.0 | 4.173 |

| 25 kV | 125.0 | 114.0 | 4.488 | 152.0 | 5.984 |

| 36 kV | 150.0 | 165.0 | 6.496 | 203.0 | 7.992 |

P to P: Phase to Phase orientation

P to G: Phase to Ground orientation

Spacing based on metal to metal dimension prior to insulation Spacing based on insulation wall thickness per application range of above table