DERAY®-VT 220 TW

Thin wall crosslinked Viton®

Thin wall fluoroelastomer heat shrink tubing suitable for use in electronic systems and components in automotive, military/aerospace and industrial applications requiring outstanding heat and fluid resistance.

Features and Benefits

- Flame retardant

- Very flexible

- Highly abrasion resistant

- High withstand to corrosive fluids in extreme temperatures up to 220°C

- Shrink ratio: 2:1

- Continuous operating temperature: -55°C to 220°C

- Shrink temperature: 160°C min.

Standards

- QPL SAE AS23053/13

Typical Applications

- Bundling and strain relief of wire harnesses in high temperature applications and Environments

- Excellently suitable for applications where severe chemical and thermal requirements are crucial

- Highly cut through resistant

- Commonly used for protection of cables against contamination by nearly all commercial hydraulic fluids, minerals and synthetic oils.

- Widely used in hydraulic equipment, aircraft manufacture and ship building applications

Market/Applications

- Generation – Renewables – Wind

- Shipboard

- Single Wall

- OEM

- Industrial

- Automotive

- Utility

- Aerospace Defense

Ordering

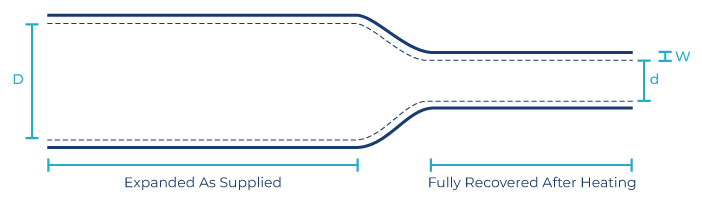

Select a dimension which will shrink snugly over the application to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Black (BK)

- Approval: Standard or QPL

- Please specify the product name, order number and options you require

- Order example: DERAY®-VT 200 TW, 0375 or 3/8in, black, QPL

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Delivery Units | |||||

| Internal Diameter (Min) D |

Internal Diameter (Max) d |

Wall Thickness (Nom) W |

Spool Lengths | |||||

| mm | in | mm | in | mm | in | m | ft | |

| 0125 | 3.2 | 1/8 | 1.6 | 0.063 | 0.80 | 0.031 | 50 | 164 |

| 0187 | 4.8 | 3/16 | 2.4 | 0.094 | 0.90 | 0.035 | 50 | 164 |

| 0250 | 6.4 | 1/4 | 3.2 | 0.126 | 0.90 | 0.035 | 50 | 164 |

| 0375 | 9.5 | 3/8 | 4.8 | 0.189 | 0.90 | 0.035 | 50 | 164 |

| 0500 | 12.7 | 1/2 | 6.4 | 0.252 | 0.90 | 0.035 | 30 | 98 |

| 0625* | 16.0 | 5/8 | 8.0 | 0.315 | 1.10 | 0.043 | 30 | 98 |

| 0750 | 19.0 | 3/4 | 9.5 | 0.374 | 1.10 | 0.043 | 30 | 98 |

| 0875* | 22.2 | 7/8 | 11.1 | 0.437 | 1.20 | 0.047 | 30 | 98 |

| 1000 | 25.4 | 1 | 12.7 | 0.500 | 1.20 | 0.047 | 30 | 98 |

| 1250* | 31.8 | 1 1/4 | 15.9 | 0.626 | 1.40 | 0.055 | 30 | 98 |

| 1500 | 38.0 | 1 1/2 | 19.0 | 0.748 | 1.40 | 0.055 | 15 | 49 |

| 2000 | 51.0 | 2 | 25.4 | 1.000 | 1.70 | 0.067 | 15 | 49 |

*Sizes 5/8in, 7/8in, 1 1/4in are MOQ items