DERAY®-ZoH 125

Halogen free heat shrink tubing

Zero Halogen & Low smoke heat shrink tubing. The product complies with the stringent requirements of the European rail norm EN45545-2 and the HL3 R22/R23 classification and even over exceeds those. The material is suitable for use in all classes required for the construction of locomotives and rolling stock. It is also suitable for use in underground environments as well as marine, military and aerospace applications.

Features and Benefits

- Low smoke generation – excellent fire safety characteristics

- Emissions of toxic fumes are well below the levels required to meet the relevant standards

- Flexible

- Flame retardant

- Good fluid resistance

- Shrink ratio: 2:1

- Continuous operating temperature: -40°C to 125°C

- Shrink temperature: 120°C min.

Standards

- EN45545-2 HL3 R22 & R23

- Meets LUL E 1042 A6

- BS 6853 vehicle category 1a

- DIN 5510

- NFPA 130

Typical Applications

Insulation of electrical components in mass transit applications, mechanical and environmental protection in the marine, military, aerospace and heavy industry, general fire safety applications where there is a risk to people or equipment

Market/Applications

- Transit

- Shipboard

- OEM

- Transit

- Industrial

- Marine

Ordering

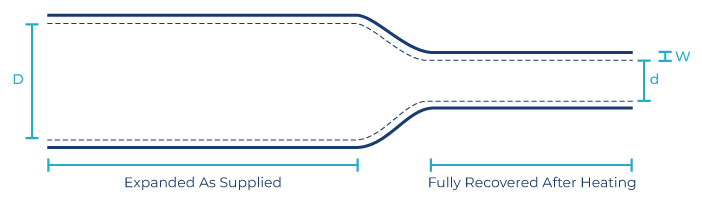

Select a dimension which will shrink snugly over the application to be covered. If recovery is restricted the resultant wall thickness will be less than specified.

- Select options:

- Color: Black (BK), yellow (YL), white (WT)

- Printing: Printed or unprinted

- Length: Continuous reels

- Please specify the product name, order number and options you requir

- Example: DERAY®-ZoH 125, 0125, BK, unprinted, 100m reel

Please contact your Customer Service Representative for information on custom colors, sizes, lengths and material data sheet.

| Order Number | Expanded | Recovered | Delivery Units | |||||

| Internal Diameter (min) D |

Internal Diameter (max) d |

Wall Thickness (nom) W |

||||||

| mm | in | mm | in | mm | in | m | ft | |

| ZoH125 0094 | 2.4 | 3/32 | 1.2 | 3/64 | 0.51 | 0.020 | 150 | 492 |

| ZoH125 0125 | 3.2 | 1/8 | 1.6 | 1/16 | 0.51 | 0.020 | 150 | 492 |

| ZoH125 0187 | 4.8 | 3/16 | 2.4 | 3/32 | 0.51 | 0.020 | 75 | 246 |

| ZoH125 0250 | 6.4 | 1/4 | 3.2 | 1/8 | 0.64 | 0.025 | 75 | 246 |

| ZoH125 0375 | 9.5 | 3/8 | 4.8 | 3/16 | 0.64 | 0.025 | 75 | 246 |

| ZoH125 0500 | 12.7 | 1/2 | 6.4 | 1/4 | 0.64 | 0.025 | 50 | 164 |

| ZoH125 0750 | 19.0 | 3/4 | 9.5 | 3/8 | 0.76 | 0.030 | 30 | 98 |

| ZoH125 1000 | 25.4 | 1 | 12.7 | 1/2 | 0.89 | 0.035 | 30 | 98 |

| ZoH125 1500 | 38.1 | 1½ | 19.0 | 3/4 | 1.02 | 0.040 | 30 | 98 |