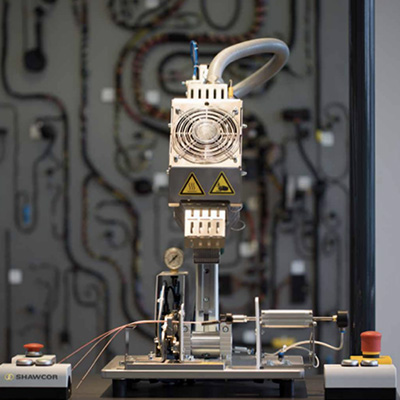

Heat-shrink machines and equipment by DSG-Canusa

Heat shrink-machines and heat shrink-equipment: in-house design made in Germany

Our DSG-Canusa Machine Technology Center (MTC) designs and manufactures both standard and customized shrink and inspection systems, to assemble and test heat-shrink applications. Engineering and manufacturing are located in the same facility, giving us the opportunity to develop high-quality heat-shrink machines, such as infrared technology equipment and hot air machines, as well as machines for testing purposes, for example, leakage testing. Providing both heat-shrink products and heat-shrink equipment makes us unique in the market. A full-service package of support before, during and after the introduction of one of our heat-shrink machines is a customer favorite. Our devices feature state-of-...Heat shrink-machines and heat shrink-equipment: in-house design made in Germany

Our DSG-Canusa Machine Technology Center (MTC) designs and manufactures both standard and customized shrink and inspection systems, to assemble and test heat-shrink applications. Engineering and manufacturing are located in the same facility, giving us the opportunity to develop high-quality heat-shrink machines, such as infrared technology equipment and hot air machines, as well as machines for testing purposes, for example, leakage testing. Providing both heat-shrink products and heat-shrink equipment makes us unique in the market. A full-service package of support before, during and after the introduction of one of our heat-shrink machines is a customer favorite. Our devices feature state-of-the-art designs that enable continuous improvement of shrink temperatures and times, a high level of operator convenience and automation, and maximum production efficiency. These high-quality attributes apply to our hot-air-based equipment, our infrared technologies and all components. In addition to the fulfilment of basic functions, we focus on high-level monitoring and continuous improvement. At the Rheinbach, Germany facility, our engineers and customers work together to develop new and different types of heat-shrink machines and shrink tunnel machines that offer superior technical performance and withstand the mechanical stresses of everyday use. Our application engineers excel at innovations that are highly flexible and efficient. By working closely with our customers, we can create solutions tailored to their needs and also support their projects from the initial use through their application's standard operating procedure and beyond. Our portfolio includes several heat-shrink machines and technologies, some examples of which are viewable on our website; we also offer fully customized solutions. Please reach out to our team to discuss your needs so that you and DSG-Canusa can build the future together. Standard features available on our appliances:- High quality and constant heat distribution for continuous reproducibility

- Modular plug and play options allow for device upgrades (instead of procuring new ones), resulting in cost efficiency and sustainability

- Poka-Yoke designed process (by software and hardware) to minimize operator influence

- Camera-based inspection systems for 100% process safety

- Full digital integration of our devices into your Manufacturing Execution System (MES)

Categories:

- Single Wall Tubing

- Dual Wall Tubing

- Medium and Heavy Wall Tubing

- High Temperature Products

- Marker Sleeves

- Braided Sleeves

- Halogen-Free Heat-Shrink Tubing

- Wildlife Mitigation

- Protection Caps

- Electrical Products

- Electrical Connection Systems

- Heat-Shrink Machines

- Water Blocking Solutions

- Market Specific Solutions

Filter by:

-

DERAY®-Shuttle 2.0

View Product: DERAY®-Shuttle 2.0

DERAY®-Shuttle 2.0

Heat shrink system for ring terminals, tubular cable lugs, end splices and battery terminals

The DERAY-Shuttle 2.0 is a heat shrink system with infrared heating elements to process heat shrink tubes onto terminals and end splices.

MORE DETAILS -

DERAY®-Shuttle 660 / 120

View Product: DERAY®-Shuttle 660 / 120

DERAY®-Shuttle 660 / 120

Heat shrink system with infrared heating elements for terminals and end splices

The DERAY-Shuttle 660/ 120 is a heat shrink system with infrared heating elements to process heat shrink tubes onto terminals and end splices.

MORE DETAILS -

DERAY®-Shuttle Vision System 2.0

View Product: DERAY®-Shuttle Vision System 2.0

DERAY®-Shuttle Vision System 2.0

The Vision System is a camera-based inspection system as a plug & play add-on for DERAY®-Shuttle 2.0. It is designed to control visual characteristics of any application like positioning of the heat shrink sleeve and the application, colors of wires and several more. The Vision System is able to control up to 64 different characteristics per monitoring step. Customer can configure a variable number of test sequences of each process.

MORE DETAILS -

DERAY®-SpliceMan IR

View Product: DERAY®-SpliceMan IR

DERAY®-SpliceMan IR

Heat shrink system

DERAY-SpliceMan IR is a heat shrink system with infrared heating elements designed to process adhesive lined heat shrink tubes onto ultrasonically welded- and crimped splice joints.

MORE DETAILS -

DERAY®-TSD Compact

View Product: DERAY®-TSD Compact

DERAY®-TSD Compact

Space-saving terminal sealing device with infrared heating

The DERAY-WorkMan TP is a hot air shrink equipment designed to process heat shrink tubes to a wide variety of applications.

MORE DETAILS -

DERAY®-TSD S-Frame

View Product: DERAY®-TSD S-Frame

DERAY®-TSD S-Frame

The DERAY®-TSD S-Frame is a terminal sealing device with infrared heating elements designed to process heat shrink tubes onto terminals and splices. The shrink device has an exchangeable frame and processes up to 20 terminals per cycle.

MORE DETAILS -

DERAY®-Vacuum-Leakage Tester

View Product: DERAY®-Vacuum-Leakage Tester

DERAY®-Vacuum-Leakage Tester

The DERAY®-Vacuum-Leakage Tester is a testing device to proof wires and cables sealed with adhesive lined heat shrink tubes against a predefined leak rate.

MORE DETAILS -

DERAY®-VaDi 2.0

View Product: DERAY®-VaDi 2.0

DERAY®-VaDi 2.0

The DERAY®-Vacuum-Leakage Tester is a testing device to proof wires and cables sealed with adhesive lined heat shrink tubes against a predefined leak rate. The DERAY®-Vacuum-Leakage Tester has an extendable amount of testing adapters. Wire cross sections between 10 mm² and 80 mm² can be tested and evaluated against a predefined leak rate. The testing device works on the principal of Δ p (leakage testing method) DIN EN 1779 - without the necessity of an additional medium.

MORE DETAILS -

DERAY®-Vision System

View Product: DERAY®-Vision System

DERAY®-Vision System

The Vision System is a camera-based inspection system as a plug & play add-on for DERAY®-WorkMan 2.0. It is designed to control visual characteristics of any application like positioning of the heat shrink sleeve and the application, colours of wires and several more. The Vision System is able to control up to 16 different characteristics per monitoring step. Customer can configure a variable number of test sequences of each process.

MORE DETAILS -

DERAY®-WorkMan 2.0 Motion

View Product: DERAY®-WorkMan 2.0 Motion

DERAY®-WorkMan 2.0 Motion

The DERAY®-WorkMan 2.0 Motion is a hot air shrink equipment with a steplessly horizontal movable shrink chamber is designed to process heatshrink tubes onto a wide variety of applications. The universal machine can be used for both pre-assembly and wire harness series production purposes.

MORE DETAILS -

DERAY®-WorkMan TP 2.0

View Product: DERAY®-WorkMan TP 2.0

DERAY®-WorkMan TP 2.0

The DERAY®-WorkMan TP 2.0 is a hot air shrink equipment designed to process heat shrink tubes onto a wide variety of applications. The universal machine can be used for both preassembly and wire harness series production purposes.

MORE DETAILS